ProSimPlus

Steady-state process simulation and optimization

ProSimPlus is a process engineering software that performs rigorous mass and energy balance calculations for a wide range of industrial steady-state processes. It is used in design as well as in operation of existing plants for process optimization, units troubleshooting or debottlenecking, plants revamping or performing front-end engineering analysis.

“We had used the same process simulator for many years and we recently have switched to ProSimPlus because it gives us good technical results, and also because we have found in ProSim a very responsive and competent technical support. They have provided us with quick and effective assistance throughout the transition phase to ProSimPlus, so that the change has been smooth. Furthermore, the software is very intuitive and easy to use, so users have adapted very quickly.”

“We had used the same process simulator for many years and we recently have switched to ProSimPlus because it gives us good technical results, and also because we have found in ProSim a very responsive and competent technical support. They have provided us with quick and effective assistance throughout the transition phase to ProSimPlus, so that the change has been smooth. Furthermore, the software is very intuitive and easy to use, so users have adapted very quickly.”

SEBASTIÁN ESPINO – R&D Manager at Ercros (Barcelona, Spain) the first Spanish basic chemicals company (www.ercros.es)

Main features

Comprehensive set of unit operations including complex models

Powerful thermodynamic package able to model highly non-ideal systems and a wide range of processes

Unrivalled convergence methods

Unique graphical user interface allowing instant usability, convenient drawing of the flowsheet and quick access to results

Open system to expand capabilities (user defined unit operations, Visual Basic scripting, CAPE-OPEN thermo and unit operation interfaces…)

Solution widely used by world’s leading oil, gas, chemicals, energy or bio-based industry players

ProSimPlus is a flexible process engineering software that performs rigorous mass and energy balances for a wide range of industrial processing plants.

It is used in design as well as in operation of existing plants for performance optimization, units troubleshooting, debottlenecking, plants revamping or front-end engineering analysis.

To design more competitive units, to operate very integrated processes closer to their limits, to face new regulations (environment, safety …), engineers cannot be satisfied with simple models anymore. They need a powerful but easy-to-use tool to simulate the behavior of their plants, to quickly test new configurations and to get the optimal solution without necessarily being a modeling expert.

ProSimPlus answers to these requirements with an environment that is convenient, easy to use, technically complete and numerically efficient.

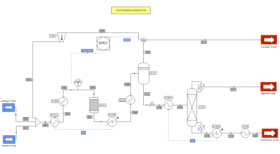

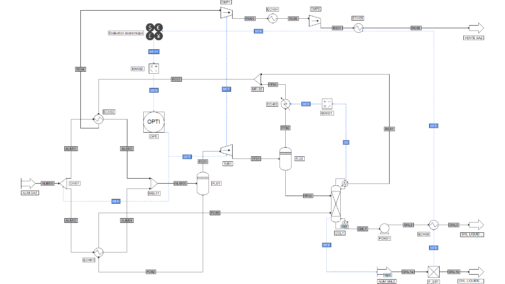

Simulation and optimization of a bioethanol production plant

A convenient and easy to use software

ProSimPlus use is very intuitive.

Users who are accustomed to another simulation tool are surprised how easy to learn ProSimPlus is and how fast they can progress with the software. As for beginners, they do not need long and expensive training to become fully operational.

ProSimPlus provides a large set of functionalities for a simple and efficient exploitation of results: fully configurable table summarizing the streams characteristics, on-line help, unit systems management, generation of results under HTML (simulation reports), MS-Excel (mass and energy balances), .BMP or .EMF (flowsheet)…

“Scriplets” provide the user with the ability to plot graph, exchange simulation files with others users, call Simulis Thermodynamics calculation services, create equipment specification sheets, etc. Scriplets are “small” VBS programs that can be used at any time, directly from the ProSimPlus flowsheet and which library can also be enriched by the user. A whole set of new functions were introduced in the new release in this fashion. They contribute in making the difference between an easy to use industrial tool and a software designed for some specialists.

The graphical interface rests on Windows standards with numerous tools to ensure fast access to information and convenient learning: information layers, color management, right click, double click, drag and drop…

ProSimPlus is also the only process simulator available in French and English.

Hardware requirements

Intel (or equivalent) based PC with:

- Computer running Windows (7, 8, 8.1, 10, 11) or Windows Server (2012R2, 2016, 2019, 2022)

- x86 or x64 processor running at 1 Ghz minimum (or 2 vCPUs for a virtual machine)

- RAM: 4 GB minimum (plus 2 GB per concurrent user for a server)

- Storage: 4 GB minimum (plus user file storage)

- Internet access: only to download the software and the license.

The ability to represent your system accurately

The solutions obtained with simple models provided by most of the simulators are probably already implemented. ProSimPlus allows the engineer to go further and to use sophisticated models to represent all the complexity of the actual plant behavior.

ProSimPlus provides over 70 unit operations among which the common operations and the more specific ones:

- Several types of chemical reactors (CSTR, PFR…) with a wide library of chemical reaction models: instantaneous, equilibrated, kinetic controlled, complex reactions…

- Multi-stage LV or LLV columns, possibly reactive for distillation, absorption or stripping

- Multi-stage separators for liquid-liquid extraction

- Multi-stage separators with transfer models – non equilibrium stage (optional)

- Multi-fluids heat exchangers (plate-fin heat exchangers)

- Solid treatment equipment (crystallizer, filters, hydrocyclone…)

ProSimPlus has functionalities to perform the sizing of most equipment: columns (packing, plates…), heat exchangers, separation vessels,… When necessary the user can create custom unit operations easily or re-use modules that were written in other environments: MS-Excel, VB, etc.

A complete thermodynamic package

The quality of a simulation rests above all on a good representation of the system thermodynamic behavior and one cannot hope to accurately represent a system without the adequate property models, in particular when it is highly non-ideal.

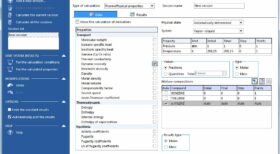

ProSimPlus provides an extensive set of thermodynamic models, selected for their reliability and robustness and a property database of over 2300 components, built on AIChE’s DIPPR®.

Simulis Thermodynamics, ProSim’s acclaimed thermodynamic server, is embedded in ProSimPlus. This allows seamless access to all kinds of physical properties calculations and in-depth analysis on the pure components or mixtures involved (see Simulis Thermodynamics documentation).

This strong basis allows representing many types of systems: oil and gas production, refining, gas processing, petrochemicals, chemicals, biochemicals, pharmaceutical, nuclear, electrolytes, coal processing, synthetic fuels, environmental, water and steam, food, food intermediates, mineral, metallurgical…

Each process can be represented accurately by combining different properties calculation methods if necessary. Additionally, the simulation can be fine-tuned by using several property models throughout the same flowsheet.

The ability to model processes with complex chemical reactions

A large number of reaction models are available to represent instantaneous or controlled kinetics reactions, equilibrated reactions and complex reactions.

Different models can be associated to different parts of the process and it is possible to integrate several sets of reaction in the same flowsheet to obtain more accurate results.

Reliable results, without time-consuming convergence tests

ProSimPlus is particularly effective in resolving complex simulation problems: processes with highly non-ideal mixtures, numerous recycling loops and design specifications, difficult separations or very large flowsheets. The fast convergence is ensured by specific algorithms based on the simultaneous modular approach. This development, unique in the world of process simulation, comprises in particular:

• Automatic determination of the calculation sequence: stream initialization and tear streams are not required;

• Simultaneous treatment of recycling and design specifications through proven methods;

• Multivariable control approach that allows imposing one or several process outputs by simultaneously adjusting one or several selected parameters;

• An advanced optimization module, based on a non-linear approach (SQP), for the optimization of operating conditions according to user defined constraints;

• Possibility to simulate only part of the process after a parameter modification, instead of running the full simulation over again.

At each unit operation level, a fast and reliable convergence is ensured by using the method best suited to the equation system to be solved (Newton, Gear…) and a generalized use of analytical derivatives.

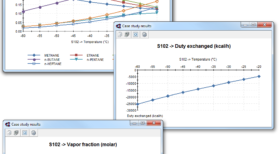

Ability to run case studies to automatically perform sensitivity analysis (the influence of a given operating parameter on a set of predefined variables).

- ProSimPlus – simulation of a bioethanol plant

- Cyclohexane plant with ProSimPlus

- Sensitivity study with ProSimPlus, process simulation software

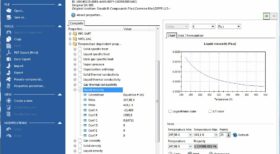

- Compound editor

- Thermodynamic model selection

- Calculation services

- Process simulation flowsheet

ProSimPlus has many applications in industries such as chemical, pharmaceutical, petrochemical, oil, gas treatment, refining, specialty chemical, and in engineering companies. Its rich thermodynamic package and its flexible architecture allow the representation of almost all systems encountered.

- Simulation of a vacuum distillation unit Process simulation with ProSimPlus – process flowsheet

- CO2 capture using an amine solution

- Simulation of the use of a heat pump

- Natural gas deacidification with the Selexol process

- Natural gas dehydration unit with TEG

- Simulation of a bioethanol production plant

- Simulation of a biofuel production process

- Economic evaluation of a toluene hydrodealkylation process

- Operating balance optimization of a natural gas liquids plant

- …

To read full application examples with ProSimPlus, go to the Resources section of the website.

Yes it is possible under certain conditions. Evaluation versions are fully functional but with a limited thermodynamic library. No downloadable version of ProSimPlus is available on the Fives ProSim web site ; so you will need to get in touch with the Sales Department who will organize this for you.

Contact us to try the software

ProSimPlus use is very intuitive. Users who are accustomed to another simulation tool are surprised how easy to learn ProSimPlus is and how fast they can progress with the software.

Fives ProSim also proposes a serie of training courses to allow you to achieve more with the software. View the training calendar

Moreover, you are not alone with the software: the Support team is available to answer your questions during the duration of your contract.

ProSimPlus is a steady state simulator, that will represent continuous processes.

It is provided with extensive libraries of unit operations, component properties databases and thermodynamic models and therefore can be used in many different industries such as chemical, pharmaceutical, petrochemical, oil, gas treatment, refining, specialty chemical.

It is also possible to add user defined unit operations and thermodynamic models to deal with specific applications and extend the application field. ProSimPlus can model complex systems (large flowsheet, with numerous recycling or hignly non ideal mixtures).

ProSimPlus is used in many different industries around the world. Here are a few examples of some common industrial processes. Customers have access to the software file in addition to the pdf of the example by connecting to the Support area of the website.

To view our application examples, click here

Flexibility is a major strength of ProSimPlus. The user has several options to use private modules in the software. The choice will mostly depend on the complexity of the module and on your programming competencies.

The “Windows Script” provides a coding environment to create additional calculation operations (calls to external data, unit operations…). The module is coded in VBScript (a simplified version of Visual Basic).

The user can also create more complex modules in the form of external dll’s, in Fortran or other languages (please consult). The UTI module of ProSimPlus allows calls to this dll and integrates it into the process flowsheet just like any other standard module.

Thirdly, ProSimPlus is one of the few simulators that implements the “Unit” interfaces of the CAPE-OPEN standard. Thus, in the flowsheet, compliant unit operations from other parties (HTRI, gProms for example), can be used without any programming. Should you have an in-house module, Fives ProSim can encapsulate it in the required CAPE-OPEN interfaces and make it usable in ProSimPlus.

Last but not least, you can always ask Fives ProSim’s development team to integrate your calculation methods and models in the sofwtare. This type of project can produce an exclusive version of ProSimPlus (that you would be the only one to use) or an enrichment of the standard version of the software.

During the calculation, different colors show you if the unit operation that is under calculation has converged or not. At the end of calculation, if the simulation has not converged, the signs remain on the module(s) that failed. A red cross means that the convergence has failed completely, an orange signs means that it has converged but a warning is attached to it. You are invited to immediately open the module configuration window and in the Result tab, you will find the explanation. This explanation is also found in the Simulation Report, generated at the end of each simulation.

If you need any further assistance, contact Support.