ProSim HEX

Heat exchangers simulation (plate-and-frame, shell and tubes...)

ProSim HEX is ProSim’s software dedicated to the simulation of heat exchangers. This software contains a module for the detailed simulation of plate-and-frame heat exchangers (gasketed plate-type heat exchangers) with or without chemical reactions, a module for the rating of shell and tube heat exchangers, as well as several modules for a simplified simulation of other heat exchangers (without taking into account the exchange technology). ProSim HEX also provides modules to simulate the auxiliary equipment nearby the heat exchangers (pumps, compressors, turbines, flashes, valves…).

Main features

A module for the detailed simulation of plate-and-frame heat exchangers, possibly reactive

A module for the rating of shell and tube heat exchangers

A library of unit operations to represent auxiliary equipment

Powerful features for detailed design and analysis: sensitivity analysis, specifications, optimization…

A rigorous and comprehensive thermodynamic library

An intuitive interface for the description of the equipment and the analysis of the results

An open software enabling the user to add their own know-how

ProSim HEX software makes it possible to simulate in a detailed way a single exchanger or a network of connected heat exchangers (in series, in parallel…) with possible recycling between the heat exchangers to represent all the complexity of a real installation.

The calculation of heat exchangers with ProSim HEX benefits from the full power of ProSim’s thermodynamic server integrated in ProSim HEX. It is known that the thermophysical properties of fluids (viscosity, specific heat…) and the thermodynamic properties (in particular, for a phase change (boiling temperature…) have a great impact on heat transfer and pressure drop calculations. Their rigorous and precise estimation, even for the most complex mixtures, is an undeniable strength of ProSim HEX.

ProSim HEX characteristics:

- A module for the detailed simulation of plate-and-frame heat exchangers, possibly reactive (CO-ProSim PHE, see description);

- A module for the detailed simulation of shell and tube heat exchangers.

- A library of unit operations to represent auxiliary equipment:

- Heat exchangers (independent calculations of the dimensions): cooler/heater, simple heat exchanger, generalized heat exchanger, multi-fluids exchanger;

- 2-phase flash (liquid-vapor): T-P, T-ω, P-ω, P-Q, P-S;

- fluids transport: pump, compressor, generalized compressor, turbine, vapor ejector, pressure drops, expansion valve, orifice plate;

- streams mixer and splitter, components splitter.

- Powerful features for detailed design and analysis: sensitivity analysis, specifications, optimization…

- A rigorous and comprehensive thermodynamic library (refer to Simulis Thermodynamics brochure);

- An intuitive interface for the description of the equipment and the analysis of the results;

- An open software enabling the user to add their own know-how: user-defined unit operations, new compounds, Visual Basic scripts, addition of external unit operations or thermodynamic models using CAPE-OPEN technology…

Hardware requirements

Intel (or equivalent) based PC with:

- Computer running Windows (7, 8, 8.1, 10, 11) or Windows Server (2012R2, 2016, 2019, 2022)

- x86 or x64 processor running at 1 Ghz minimum (or 2 vCPUs for a virtual machine)

- RAM: 4 GB minimum (plus 2 GB per concurrent user for a server)

- Storage: 4 GB minimum (plus user file storage)

- Internet access: only to download the software and the license.

CO-ProSim PHE: Simulation of Plate-and-Frame Heat Exchangers

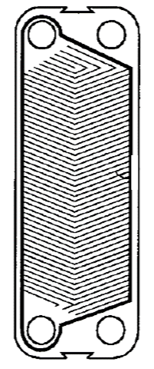

Many industries such as food, chemical and pharmaceutical … use gasketed plate-type heat exchangers because they are compact, efficient and easy to clean. They also allow a great flexibility by easily adjusting the number of plates depending on the expected operating conditions. The simulation of gasketed plate-type heat exchangers, possibly reactive, with a dedicated module (CO-ProSim PHE) will allow the design engineer or the operator to know the characteristics of the two fluids at the outlet of the exchanger according to the characteristics of the exchanger: number and type of plates, dimensions, fouling… Thanks to a realistic modeling of the equipment, CO-ProSim PHE makes it possible to design this type of exchangers, to easily increase their performance or to adapt the heat exchangers to new operating conditions. gasketed plate-type heat exchangers – Chevrons

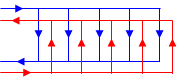

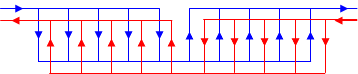

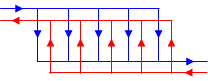

The most diverse and complex configurations can be simulated with CO-ProSim PHE: single-pass or multi-pass, countercurrent or co-current, single-phase or two-phase heat exchangers (condensation, evaporation).

The CO-ProSim PHE module also makes it possible to take into account chemical reactions in order to simulate compact reactor-exchangers that are used in particular for process intensification.

CO-ProSim PHE is independent of any plate manufacturer and allows the solutions of different suppliers to be compared impartially. Calculations of heat transfers and pressure drops will depend on the geometric characteristics of the plates (dimensions, height and angle of the chevrons …) with appropriate correlations.

Beyond the simulation of a given heat exchanger, it is possible in the ProSim HEX environment to perform a sensitivity analysis by varying one of the parameters of the exchanger and by analyzing the impact on the heat transfer and pressure drops. The use of specifications on the output fluids will make it possible to automatically add the characteristics of the exchanger to meet the expected process conditions. The design of a heat exchanger capable of achieving a given exchange is then possible.

Characteristics of CO-ProSim PHE:

ProSim HEX can simulate most configurations of gasketed plate-type heat exchangers:

- Single-pass or multi-pass,

- for monophasic or diphasic exchanges (liquid-vapor),

- in co-current or counter-current flow,

- for plates with chevron angle from 0 to 90 degrees.

A detailed and accurate thermo-hydraulic model:

- simulation of phase changes (condensation, evaporation …) and associated geometrical features;

- taking into account the heat levels of the plates located at the ends of the exchanger to simulate the reality of the operation of the exchanger and thus optimize the heat transfer;

- taking into account possible chemical reactions with different rate models (Arrhénius, Langmuir, provided by the user);

- the effects of maldistribution of the streams in the stacking sequences can be quantified;

- taking into account a possible fouling coefficient for each fluid flow;

- simulation of a process with a fluid circulating successively in more than one heat exchanger (stacking is taking into consideration).

User friendly and easy-to-use software:

- simple menus allow easy access to the geometric parameters required to describe the various plates and design the different possible configurations of the exchanger;

- the choice of a predefined plate material (stainless steel, aluminum…) or the input of the coefficients of a correlation for the calculation of the thermal conductivity for other materials;

- the choice of methods to calculate the thermal and hydraulic performance of the plates: predefined correlations or tabulated entries (point-by-point or copy/paste of an existing table) performance data (Reynolds number, Fanning coefficient, Colburn coefficient);

- a systematic control of the data consistency to eliminate unavoidable data entry errors;

- a graphical view of the configuration of the exchanger.

A complete thermodynamic package:

the determination of the fluids thermophysical properties (viscosity, specific heat…) as well as the thermodynamic properties and in particular the values of the phase changes (boiling temperature…) is ensured by the Fives ProSim thermodynamic server (refer to Simulis Thermodynamics brochure) integrated in ProSim HEX:

- a properties database containing the properties of the main fluids commonly used in heat exchangers but also complex processes fluids (more than 2 300 pure components);

- Thermodynamic properties calculation methods used to simulate heat exchangers containing all type of mixtures (hydrocarbon mixtures, polar compounds, electrolytic solutions …);

- easy editing of the various compounds’ properties;

- graphic visualization of the properties from the process flowsheet;

- The possible use of CAPE-OPEN “property packages” (combining a list of pure components and a thermodynamic model) from third-party thermodynamic servers.

The properties can also be provided by the user in a tabulated form (point-by-point or copy/paste of an existing table) for each of the two fluids: temperature, vaporization rate, enthalpy and properties of each phase (liquid and vapor): density, specific heat, viscosity and thermal conductivity.

Simple and fast use of results:

- all relevant information easily available: fluid temperature, plate temperature, fluid pressure, pressure drop, heat transfer coefficient, vaporization rate;

- summary tables with all the characteristics (temperature, pressure, heat transfer coefficient, mass enthalpy, mass vaporization rate);

- overall and localized results;

- graphic visualization of the evolution of the temperature for each fluid on any specific part of the exchanger to quickly detect performance issues.

Open software in which the user can easily add their own exchange correlations, their own materials, their own kinetics models for chemical reactions or enrich the database with new fluids properties.

Besides the ProSim HEX environment, CO-ProSim PHE is also available in other Fives ProSim software environments (ProSimPlus, ProSimPlus Energy, ProSimPlus HNO3). This module can also be accessed from any environment that is CAPE-OPEN compliant (contact us to learn more about the licensing options).